It's the interaction that counts

The success of applications with motor control depends on the selection and complex interaction of their motor control components. On the one hand, it is important to select the right motor for the application. Secondly, it is important to synchronise the motor movements and create smooth communication between all system components. In practice, three motor types predominate: the DC = direct current motor (brushless or brushed); the stepper motor (also known as a stepper motor); and the servo motor. We offer motor drivers for all types in our range . All of our products come from renowned manufacturers and offer the best price/performance ratio. Drives for motor types other than those mentioned can be found in our 'Other motor control' category.

The areas of application of the motor control unit

Motor controls are indispensable in the industrial sector, but also in the private and public sectors. They increase the efficiency and reliability of motor performance. Here are some examples of applications:

-

Industrial automation, for example in the automotive, food and packaging industries

-

Robotics

-

Control of lift motors

-

in 3D printers

-

Crane controls

-

Aviation electronics

-

Operation of CNC machines

-

in the control of pumps

-

in the control of ventilation technology

-

in e-vehicles and hybrid vehicles

A brief overview of the advantages of motor control

The driver provides the motor with precisely metered energy according to its application. The controller redirects the energy precisely into speeds and positions. The result is efficiency:

-

With our motor control system, you will always be able to operate according to demand and thus significantly reduce your energy costs

-

Electromagnetic emissions are minimised

-

the system runs more reliably and requires less maintenance

-

The operating configuration can be restored more quickly after an unplanned stop

-

Planning/programming time is also reduced thanks to our intelligent motor drivers

Motor types and motor control

The design of the motor and its control system go hand in hand. The choice of motor depends on your project.

The DC motor and its controller

Brushless DC motors impress with their low maintenance and long service life. They are used wherever efficiency and smooth, quiet running are required. With our DC motor driver, you can achieve precise speed adjustment with high efficiency.

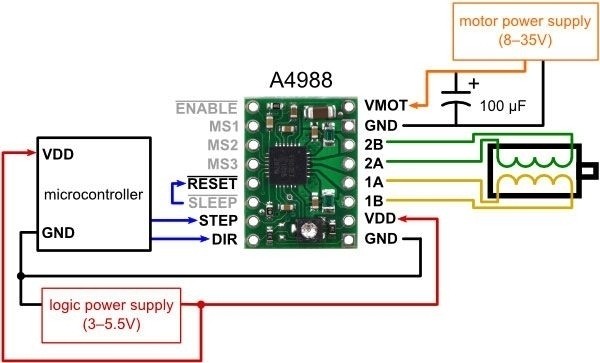

The stepper motor and its control system

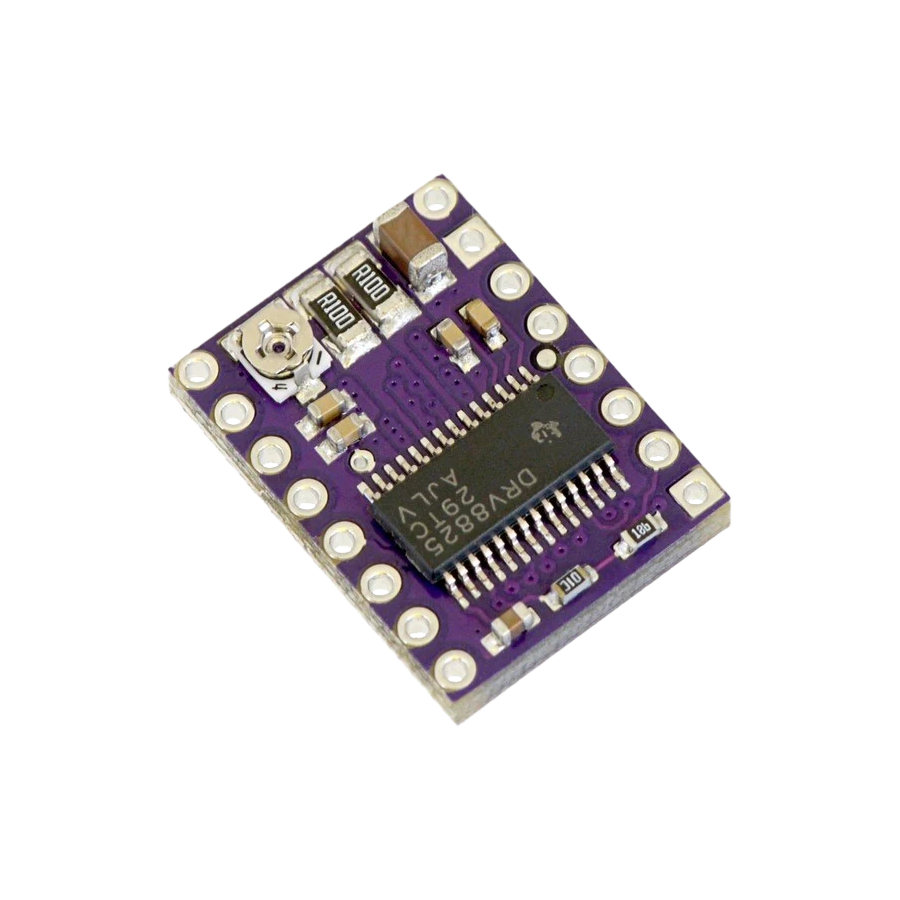

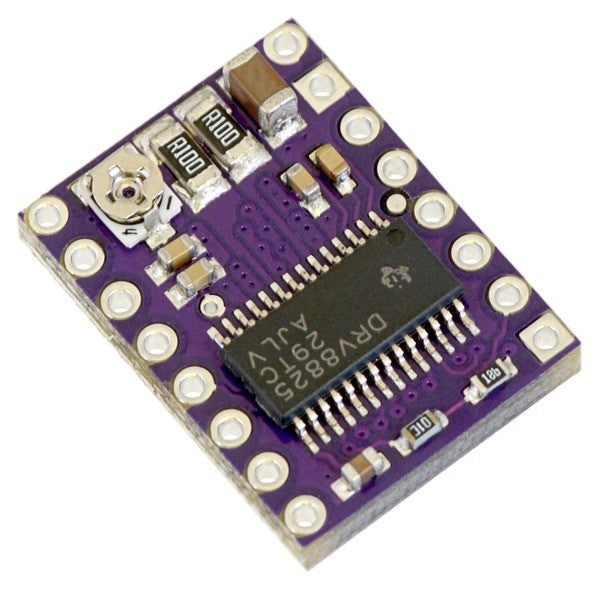

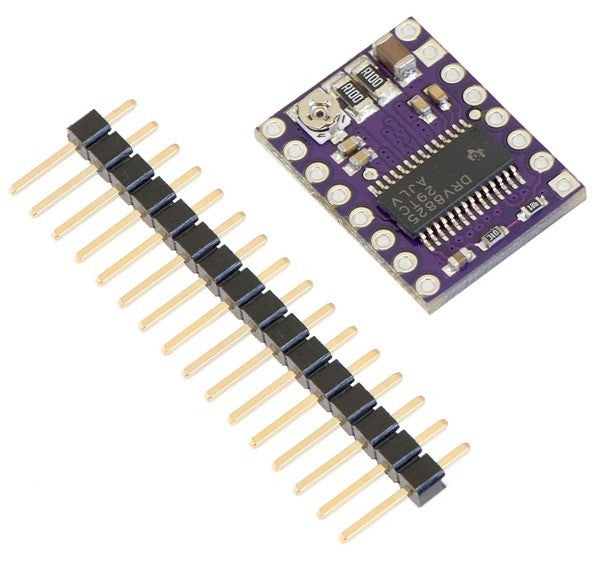

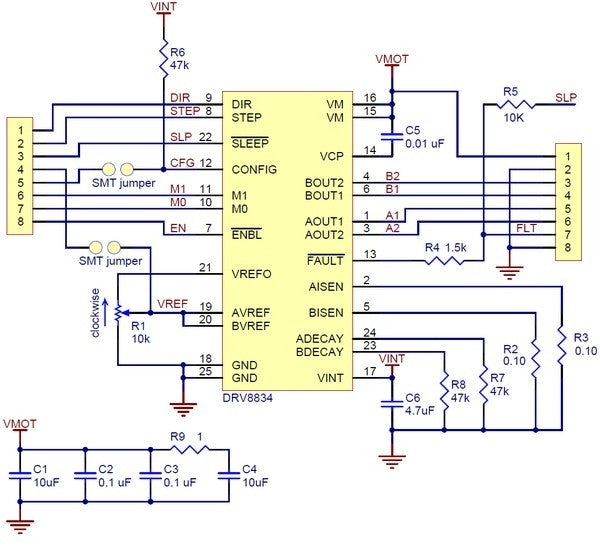

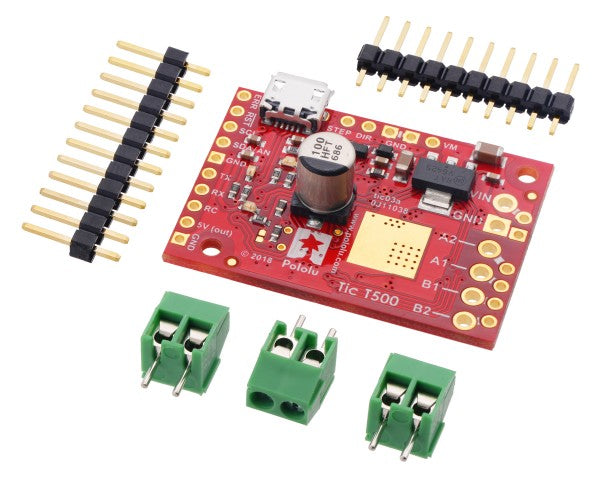

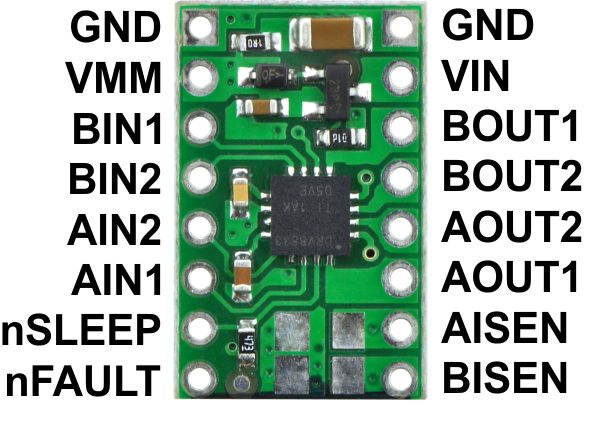

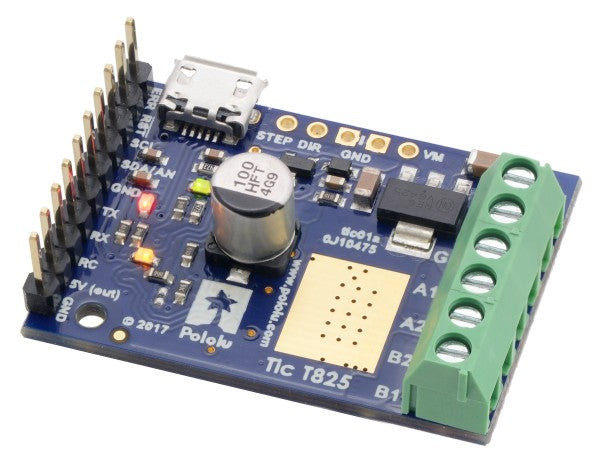

The stepper motor is an electric motor that not only rotates, but also enables precise positioning. This requires fixed magnets and magnetic coils in the motor as well as stepper motor drivers that control these magnetic coils. The stepper motor is used in industrial robotics, for example. Our stepper motor drivers increase its efficiency and precision.

The servo motor and its control unit

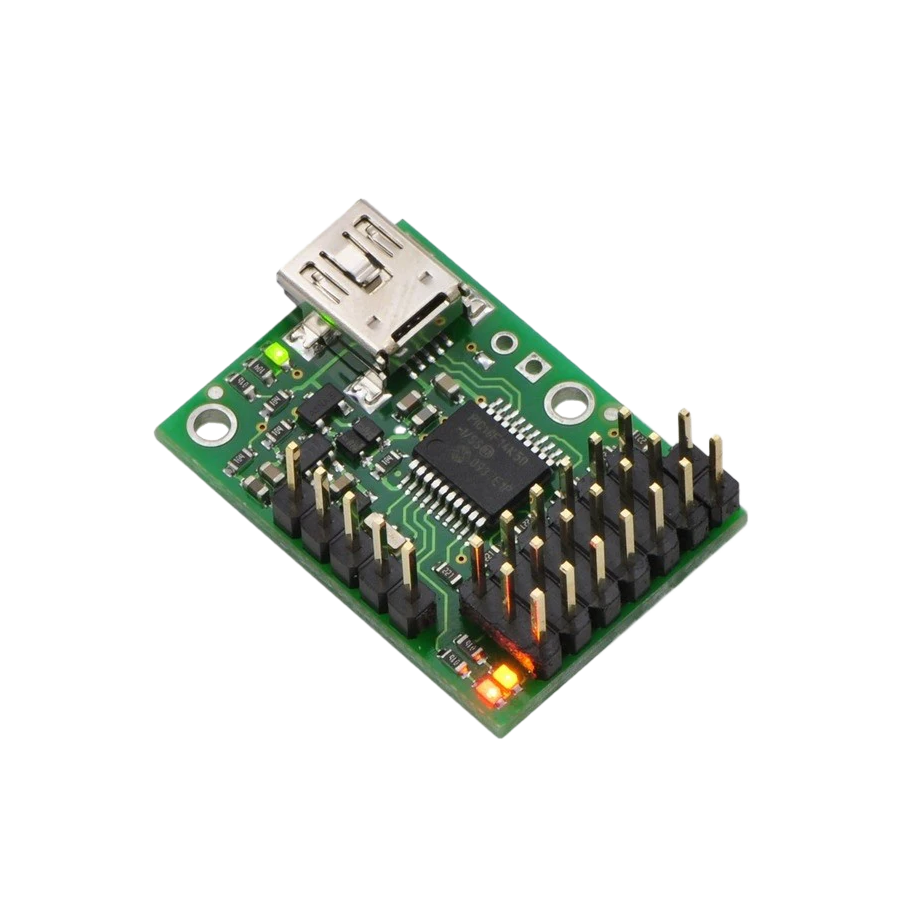

The servo motor generates a high degree of dynamics and customisation. Precise speeds and torques can be determinedwith our servo motor driver. A long service life, low initial costs and low maintenance requirements make the servo motor and driver indispensable in robotics, automation and additive manufacturing processes, for example.

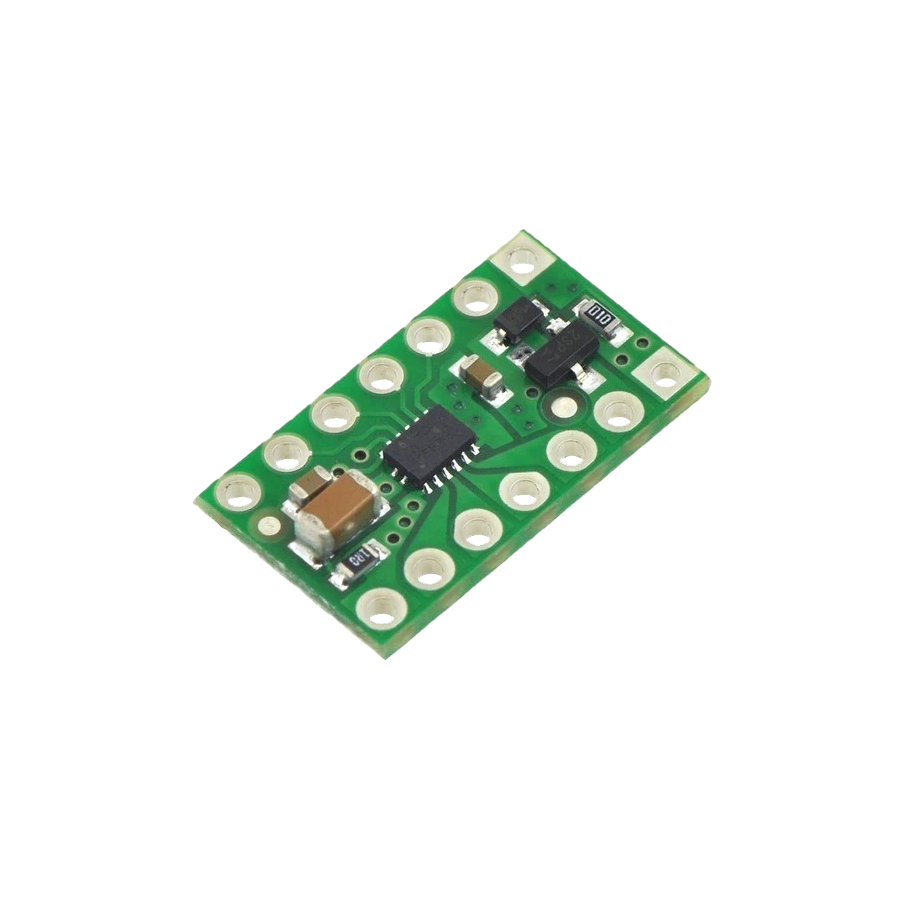

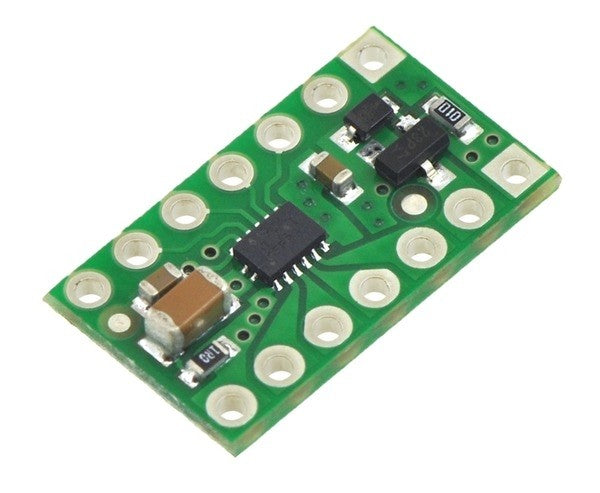

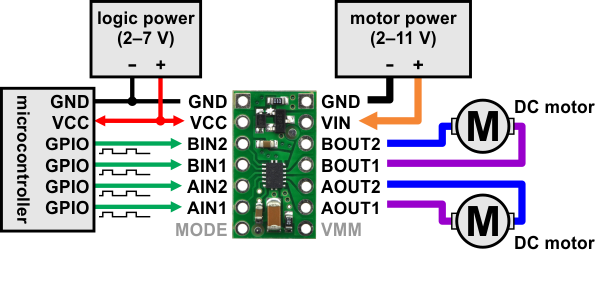

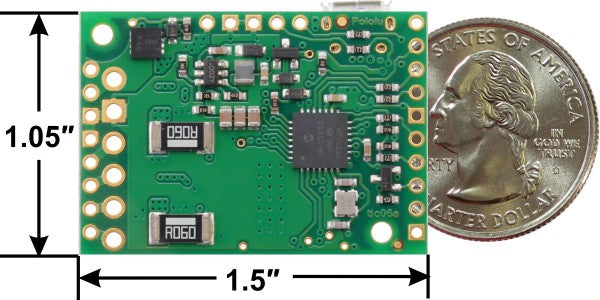

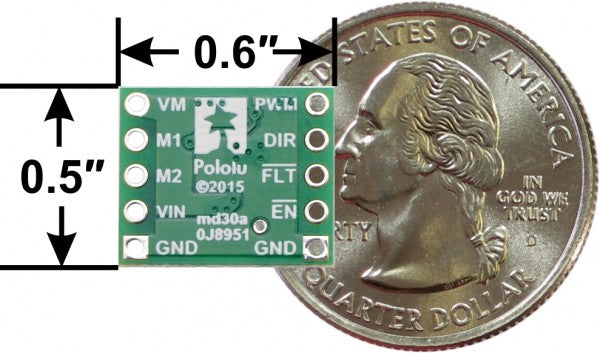

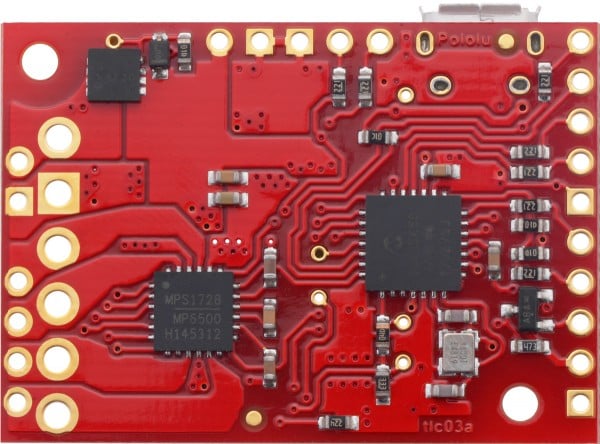

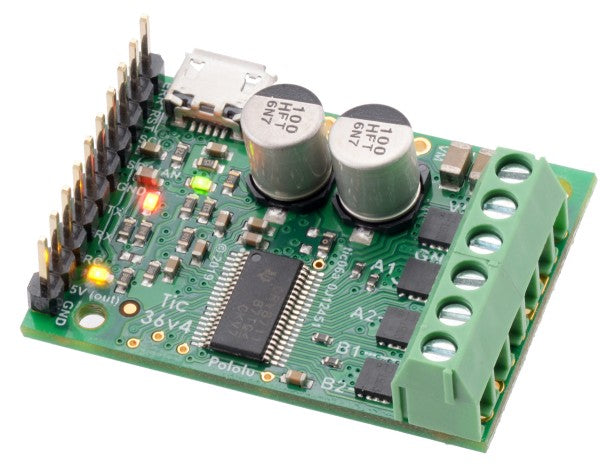

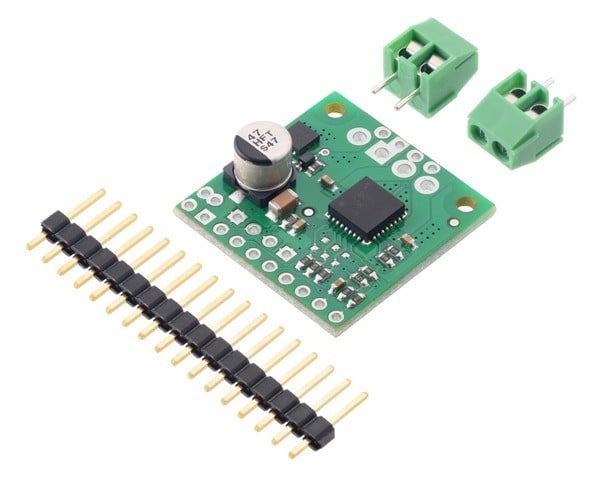

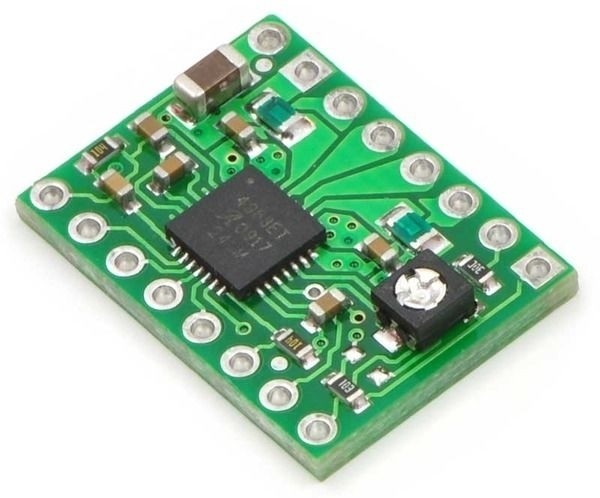

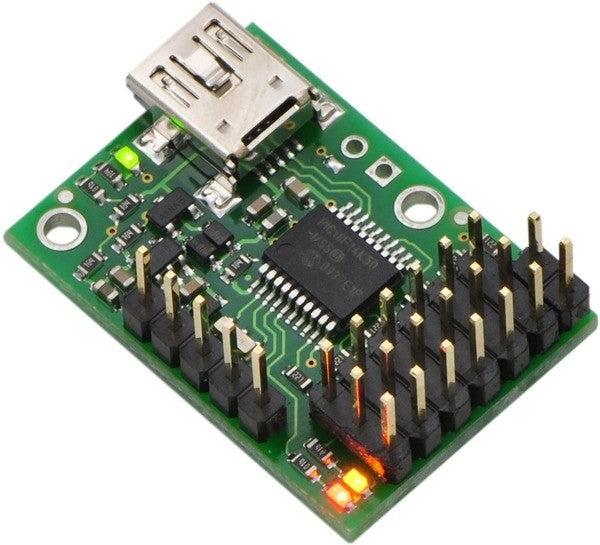

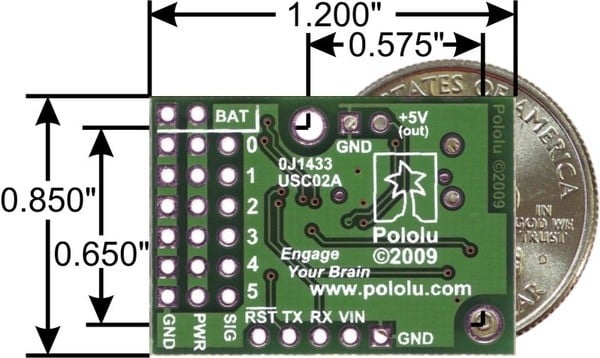

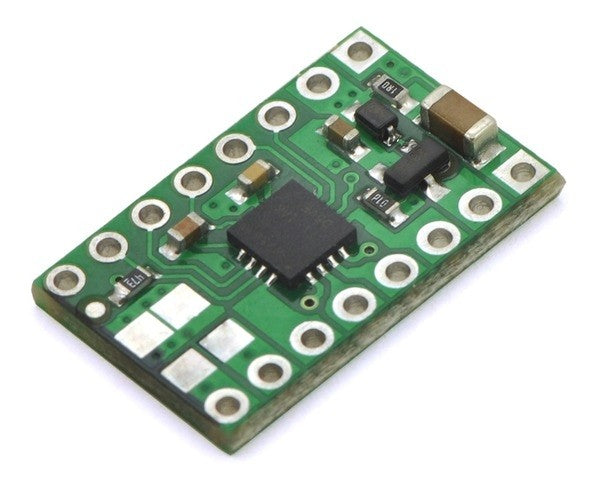

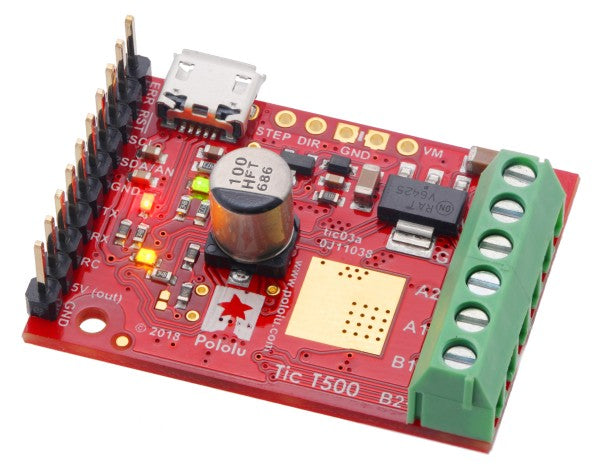

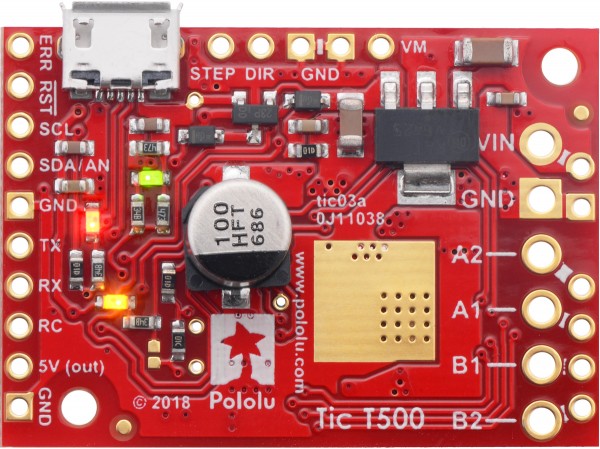

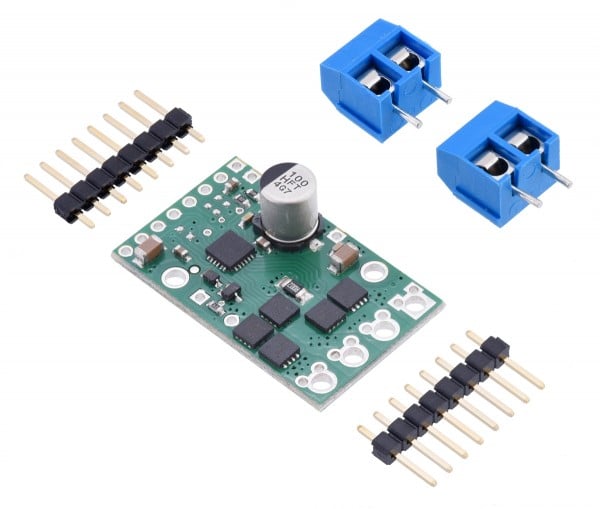

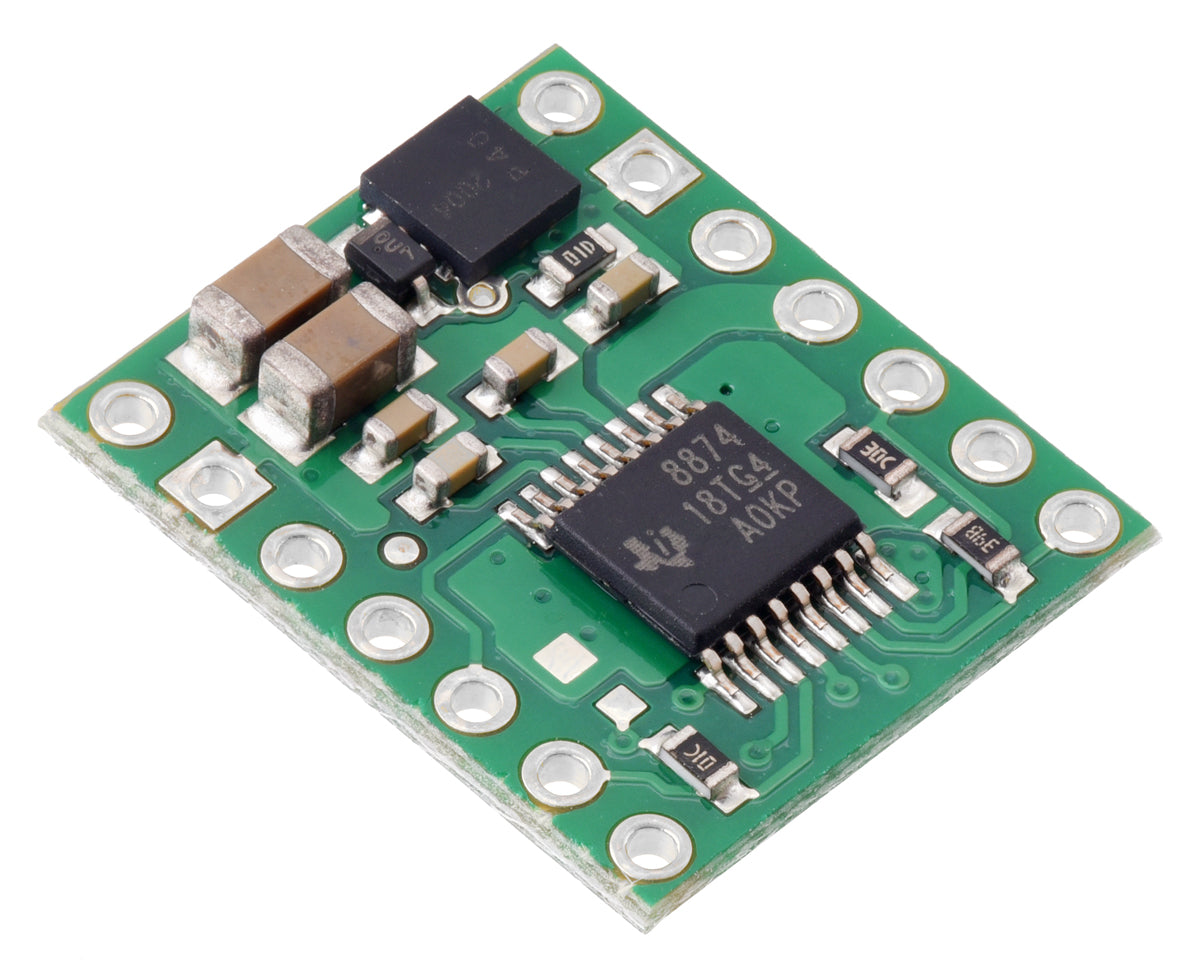

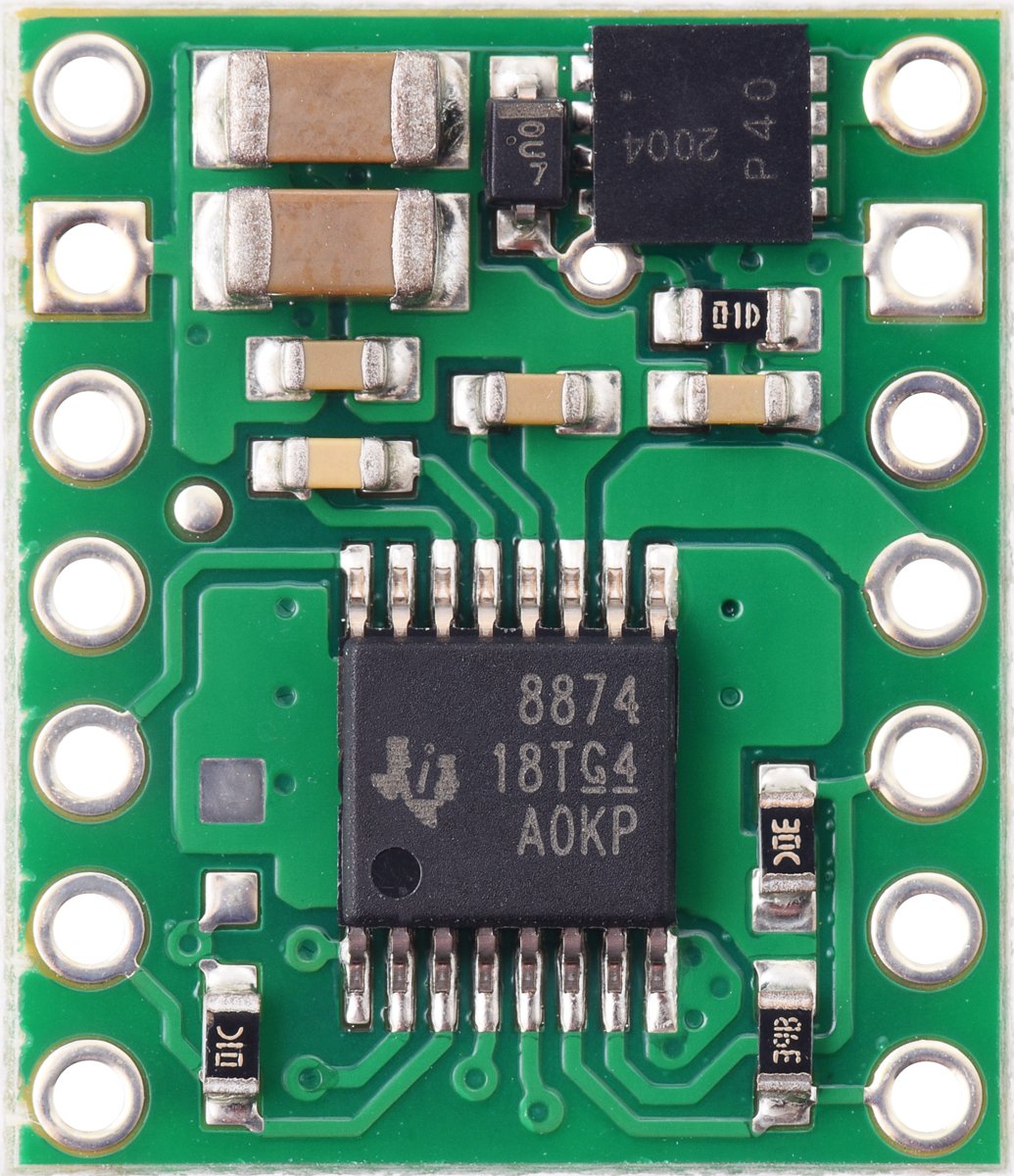

Pololu motor driver: E

Frequently asked questions about engine control

High quality and completeness: these are the guiding principles of our product range. We have put togethermotor drivers, microcontrollers and Arduino applications for all types of motor. We make technology simple and convey the joy of progress. Email us if you have any questions about our products and their possible applications.

Are there Arduino motor drivers?

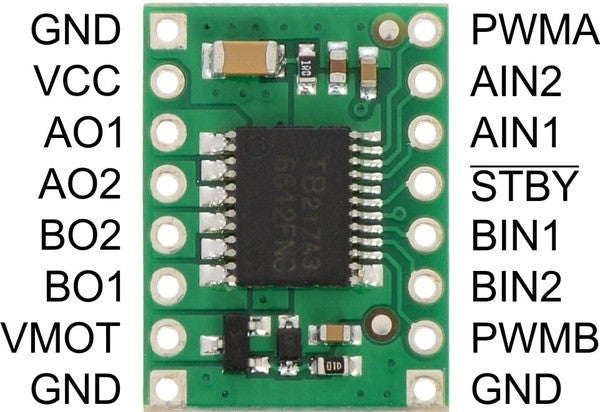

Arduino has become an integral part of control technology. We offer motor drivers with which you can control two or more DC high-performance motors via your Arduino board or an Arduino-compatible board.

How can I recognise a good motor control unit?

The price. A good price/performance ratio means: you get technology at a reasonable price (often reduced by us) that fulfils its task precisely and for a long time. Manufacturers such as the US company POLOLU offer you realistically priced top products. Extremely low prices from obscure manufacturers are not to be trusted in this market.

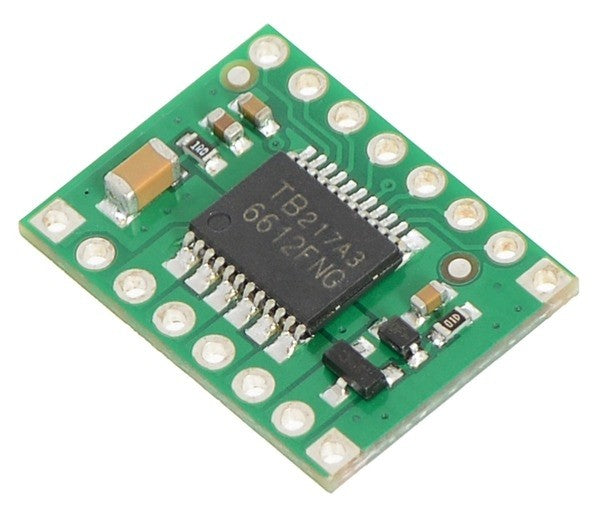

What advantages do Pololu motor drivers offer?

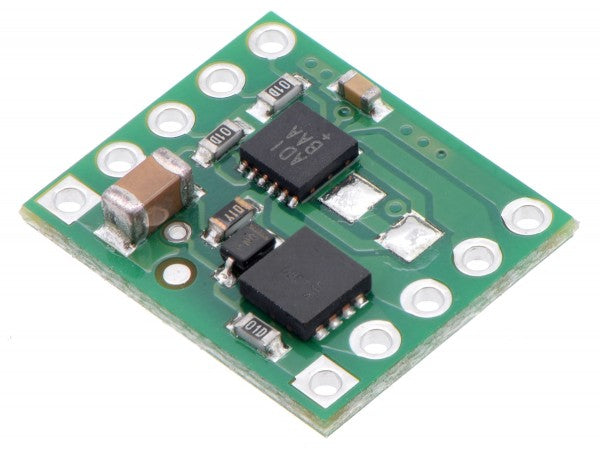

Pololu motor drivers have many advantages:

-

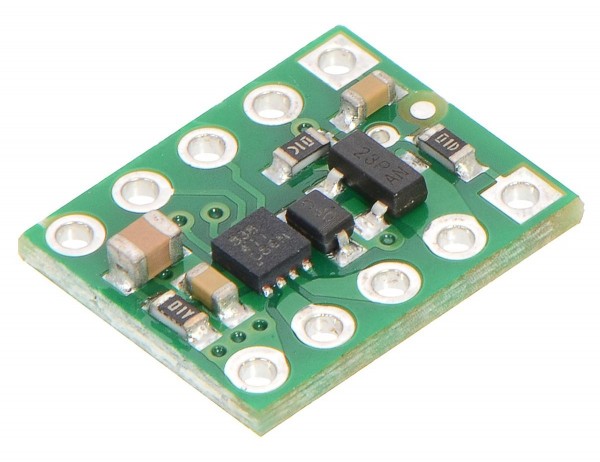

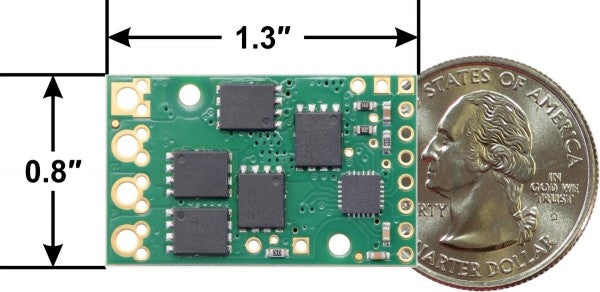

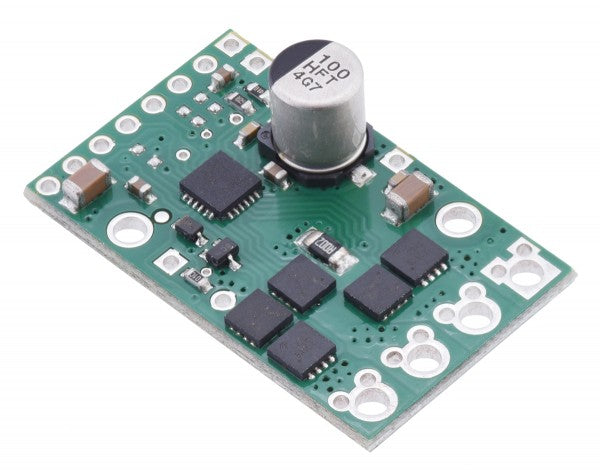

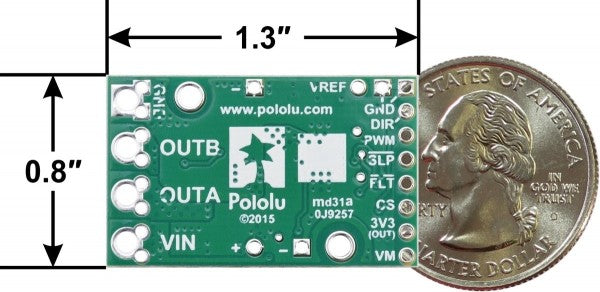

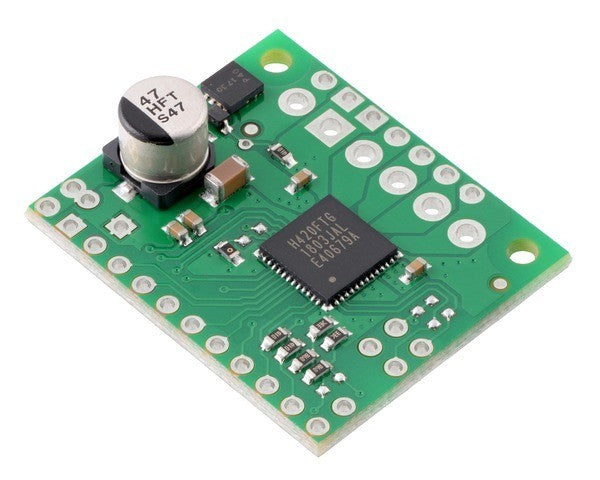

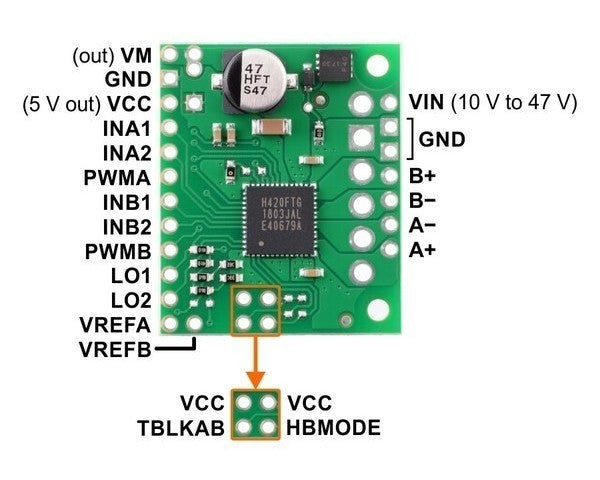

Compact design: Space is often limited in robotics or embedded systems.

-

Protective functions: Many Pololu motor drivers have integrated protection mechanisms such as overcurrent, overtemperature and undervoltage protection, which ensures the service life and safety of both the driver and the motor.

-

Wide compatibility: covers DC motors, stepper motors and servomotors

-

Detailed settings: Many models offer adjustable current limits that allow fine control of motor power, which is especially important in precision applications.

-

Easy integration: The documentation for our Polulu products is excellent. The motor drivers can therefore be easily integrated into various projects and systems.

-

High efficiency: Pololu incorporates energy efficiency into its design concepts. The motor drivers manage the energy efficiently, minimising energy losses and ensuring optimum motor performance.

Which motor control do I need for my 3D printer?

A stepper motor driver is used here. It generates the fast and precise positioning required for this printing process.