Mini-motors for technology & industry – typical applications

You can use small electric motors to equip your devices, machines and industrial products in a targeted way. The motor acts as a drive and is the centrepiece of the respective application. The range of possible application environments is huge.

- Motors as a component of industrial systems

- Drives for robotics

- Tool motors (commercial and private devices)

- Drive technology in household appliances such as kitchen appliances

- Motors in office technology such as printers, copiers and shredders

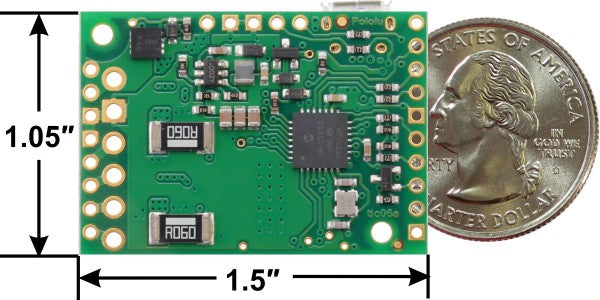

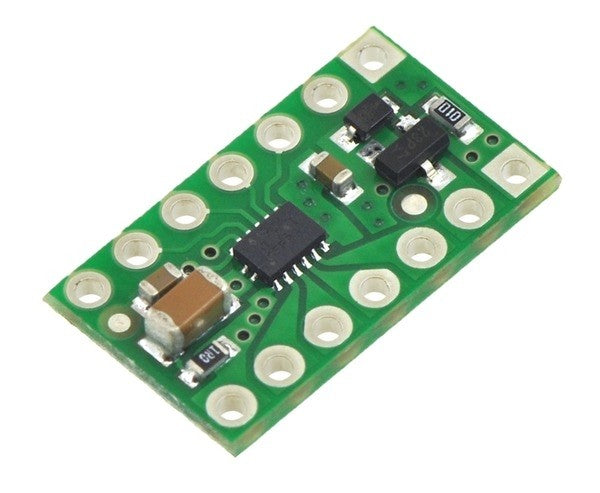

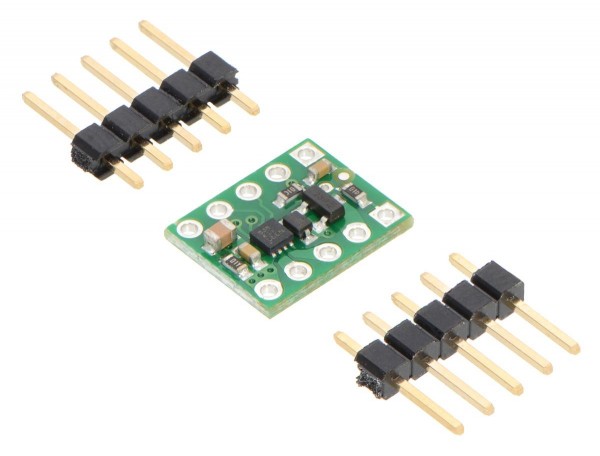

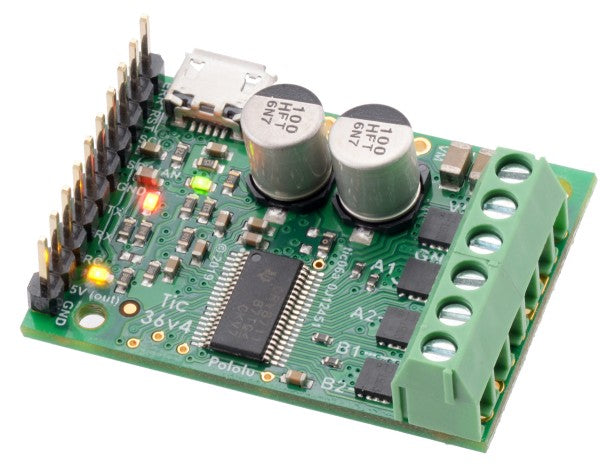

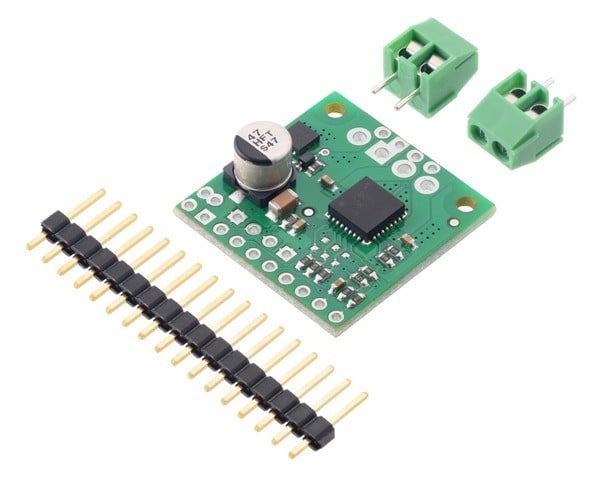

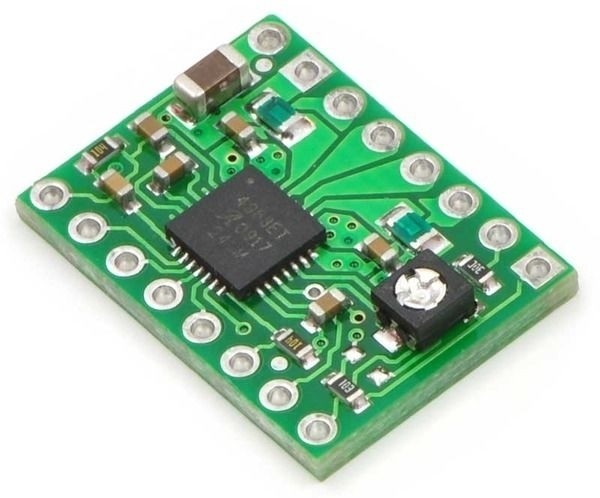

For these and many other challenges, you need compact and lightweight yet efficient electric motors. Proven solutions from providers like Pololu can be found here in the shop.

Types of motors: These electric motors are available

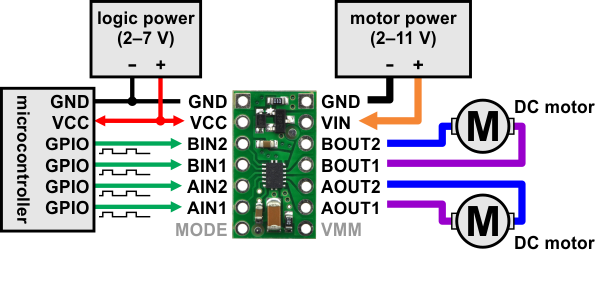

Electric motors can be divided into several subcategories. The most important criterion: is it a DC motor or an AC motor? For many industrial applications, companies use DC motors, also known as DC motors.

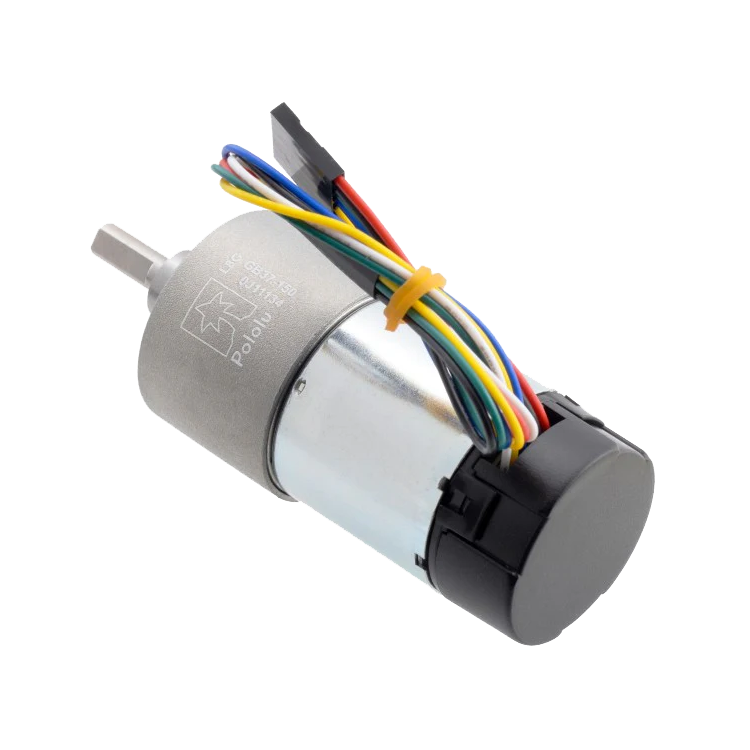

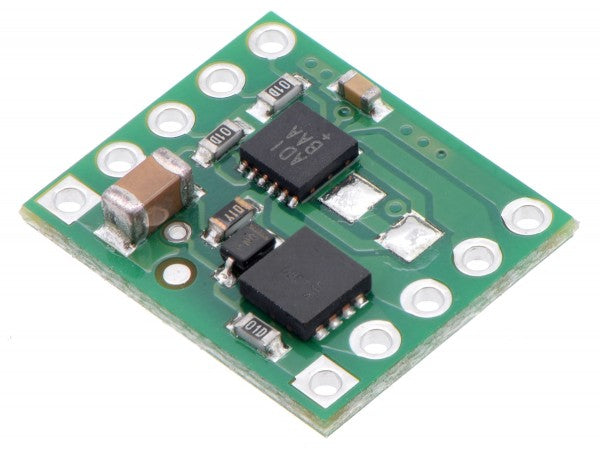

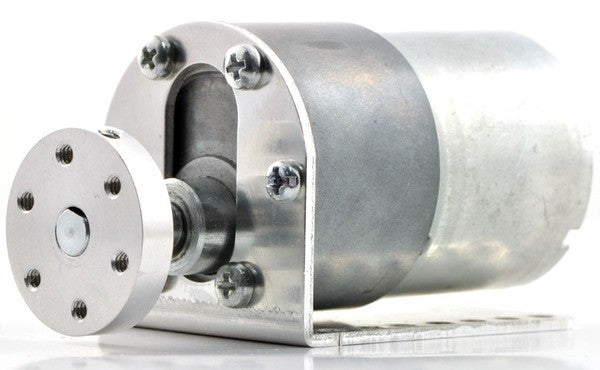

DC motors and DC gearmotors: an overview of the advantages

All DC motors are based on alternating current and a magnetic field. A commutator inverts the current flow – essential for direct current to ensure the smooth rotation of the rotor. DC gearmotors, which have a gearbox in addition to the motor, are particularly common. This combination reduces the external speed and increases the torque.

A DC motor is characterised by several advantages:

- simple but efficient functioning

- easy installation

- low costs

- starting at high speed

- flexible control of the speed in a wide range

Special motor types – an overview

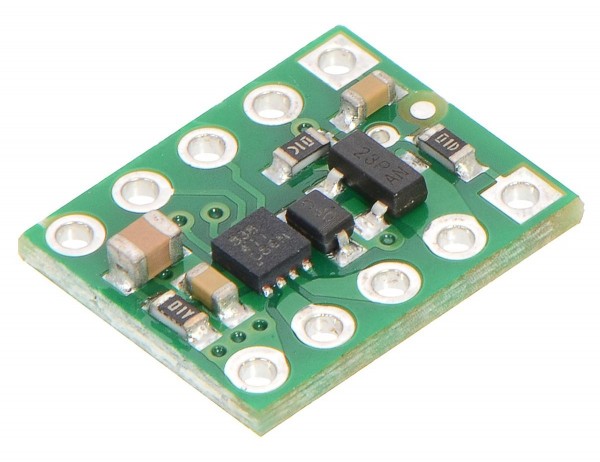

In addition, there are many other subcategories of motors that you can buy either as a DC or AC motor. These motors are characterised by additional functions such as precise motion control or vibration.

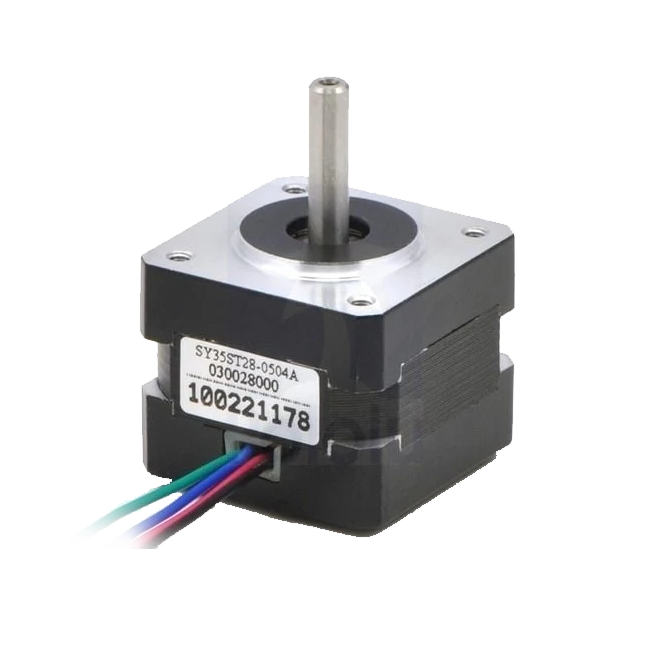

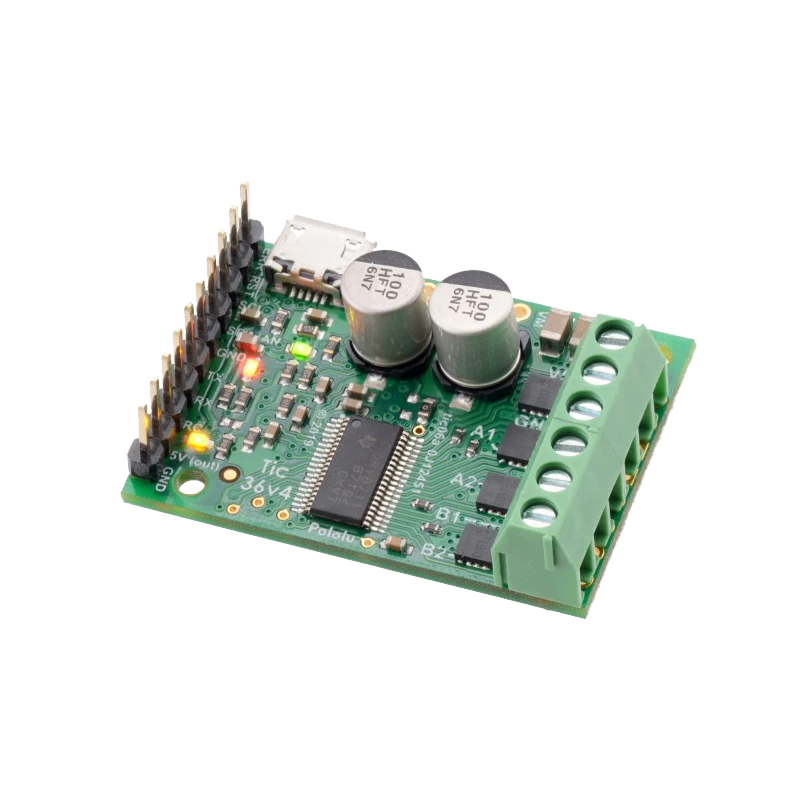

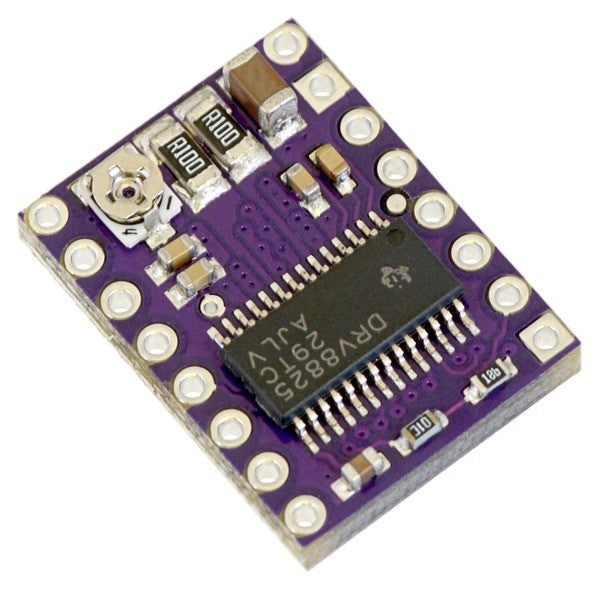

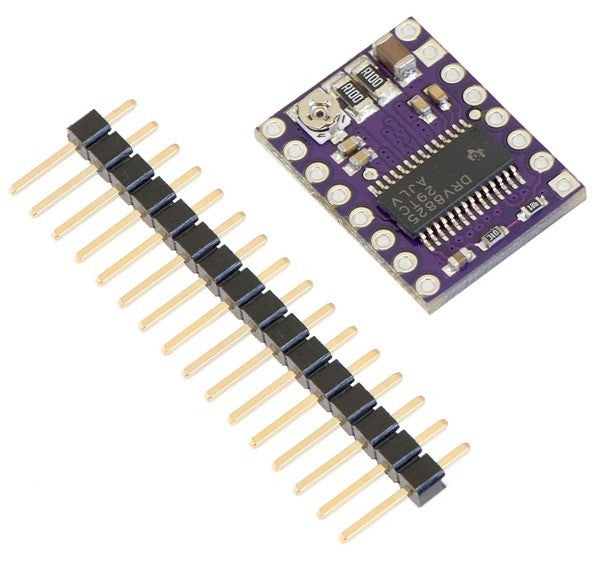

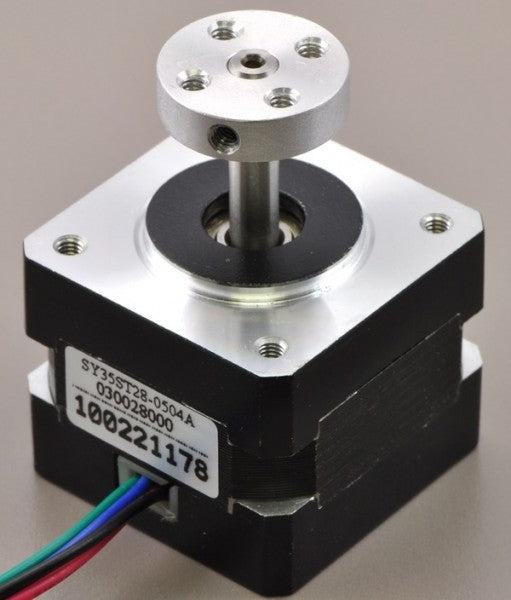

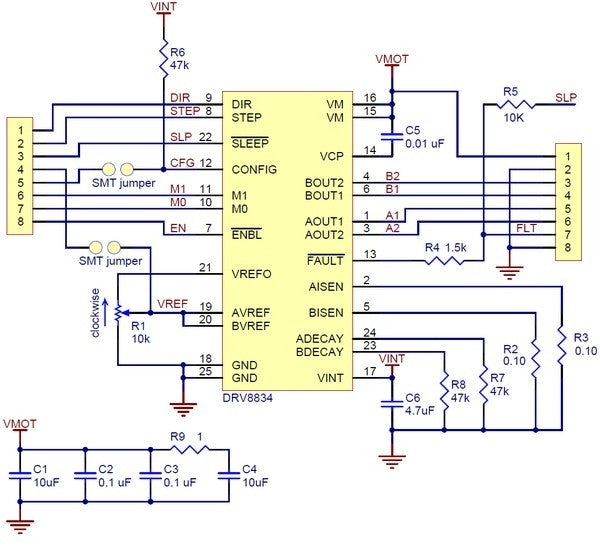

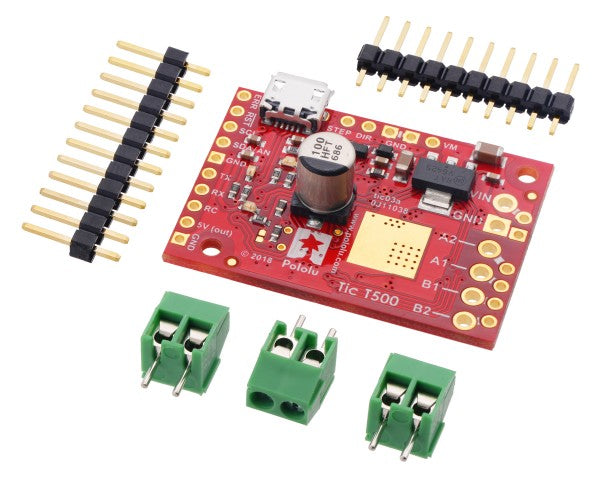

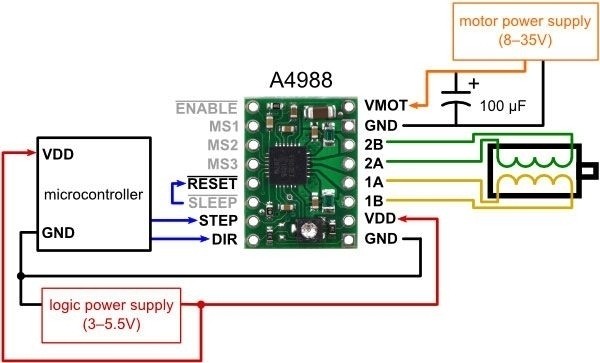

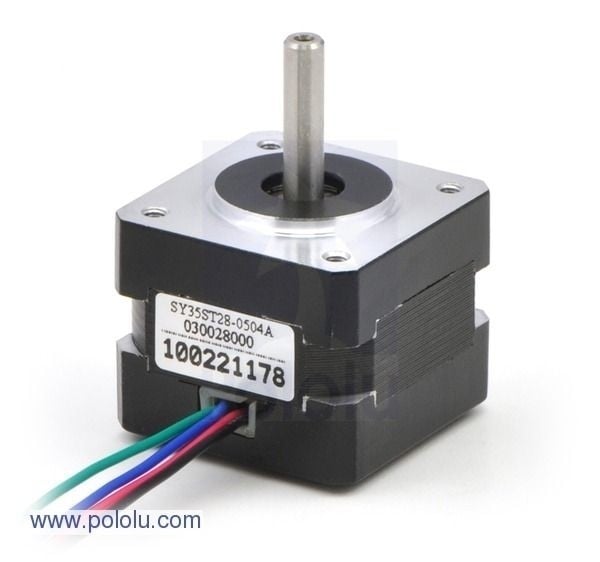

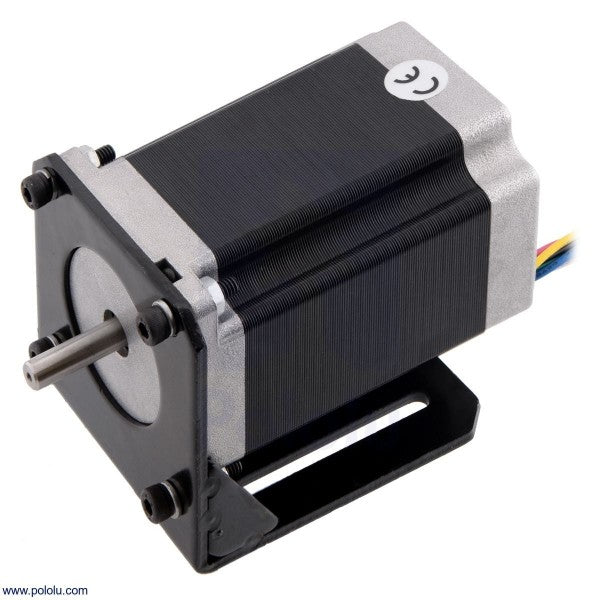

Stepper motors: a cost-effective solution

Stepper motors are used when the motor is intended for precise positioning. A typical application is the motor of a printer. Stepper motors are also used in machine tools to move the tool to the desired position. An important advantage is the simple design, which has a positive effect on the price.

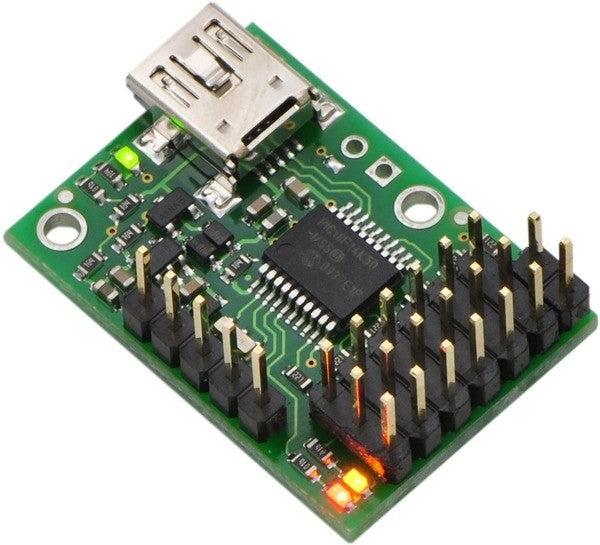

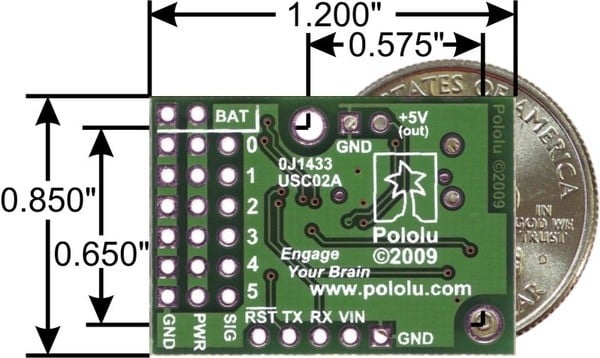

Servo motors: high-precision motion control

A servo motor performs the same function as stepper motors, but has sensor and control technology. The sensor provides real-time feedback to prevent inaccurate positioning. Servo motors are suitable for demanding applications in industry, model making and many other areas.

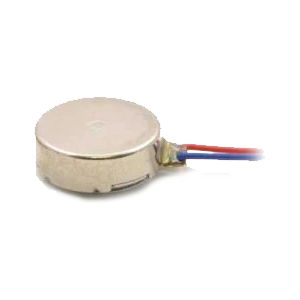

Vibration motor: motor technology with vibration function

A vibrating motor is characterised by the fact that it triggers a vibration. Electrically operated vibrators can be found, for example, in all smartphones. The vibration serves different purposes, with the smartphone vibration motor increasing user-friendliness. However, these motors also provide valuable services in laboratory equipment or industrial applications.

Buying a specific motor: these aspects are important

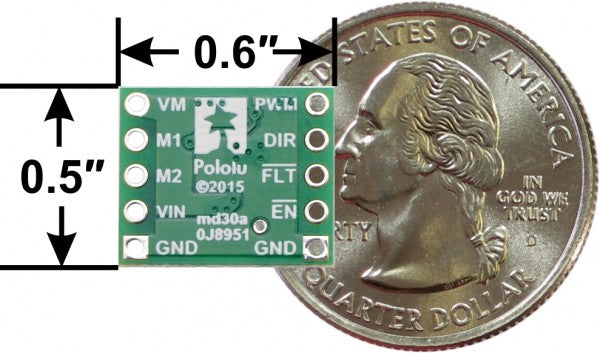

If you are looking for the right motor or gear motor for your project, there are a number of criteria that deserve your attention. Here in the shop, you can choose from hundreds of models. Pay particular attention to the following points:

- Speed (measured in rpm)

- torque (measured in Nm)

- gear ratio (for geared motors)

- weight and dimensions

- rated voltage

Quality motors for precise and durable drives

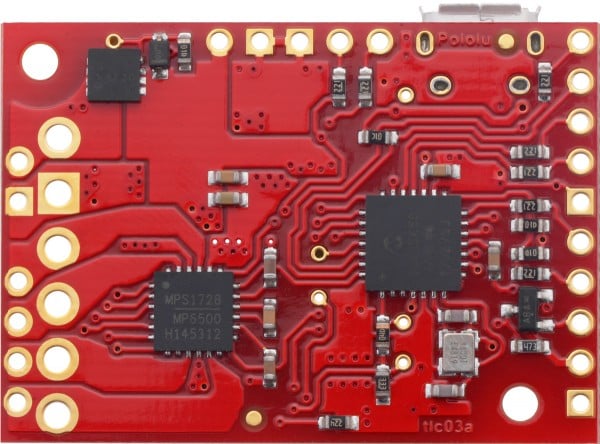

Motors are at the heart of many technical applications – from household appliances to industrial automation. A well-thought-out choice of motor technology pays off: those who choose long-lasting and powerful models reduce costs in the long term and increase operational reliability. Pololu and Feetech motors, known for their precision and reliability, have proven particularly useful. Invest in quality and optimise your production with motors that offer maximum efficiency and an excellent price-performance ratio. Discover the right model for your requirements in our specialist shop.