DC motor: design and function

How does a DC motor work? The design of a DC motor is straightforward, consisting of three main components:

- Stator: the stator forms the casing and generates a magnetic field.

- Rotor: the rotor is the moving part, consisting of thin sheets and windings.

- Commutator: This component acts as a pole reverser, ensuring that the rotor turns smoothly.

The way in which DC motors work is based on magnets. The opposing polarity drives the rotor, but without the commutator it would only be enough for a 180-degree turn. The commutator reverses the polarity of the current flow, and contact with the rotor winding is made via brushes. Carbon brushes are usually used. These brushes may increase the maintenance effort: depending on the design, you may need to clean your DC motor at certain intervals. An alternative are brushless DC motors.

The advantages of DC motors

DC motors have a number of relevant advantages over AC motors. One major plus point is that these motors can be precisely controlled. The rapid acceleration at the start also proves to be an advantage. The most important properties at a glance:

- Exact speed control in a wide range

- High starting torque

- Low power consumption

- Quiet

DC motors are used here

Motors with direct current can be found in numerous technical components. The special mode of operation of DC motors is very popular in model making, for example. Manufacturers also often use a DC electric motor for toys; the same applies to small household appliances such as fans and entertainment electronics.

DC motors also play an important role in automotive and tool manufacturing, as well as in robotics. With the customised DC motor control, a wide range of tasks can be performed: for example, the motors move valves or operate pumps.

For special purposes, users rely on DC variants such as servo motors. One of the features that characterise servo motors is that they can be used to precisely control a position. This is important for printers, among other things.

Wide range of DC motors: comparison criteria

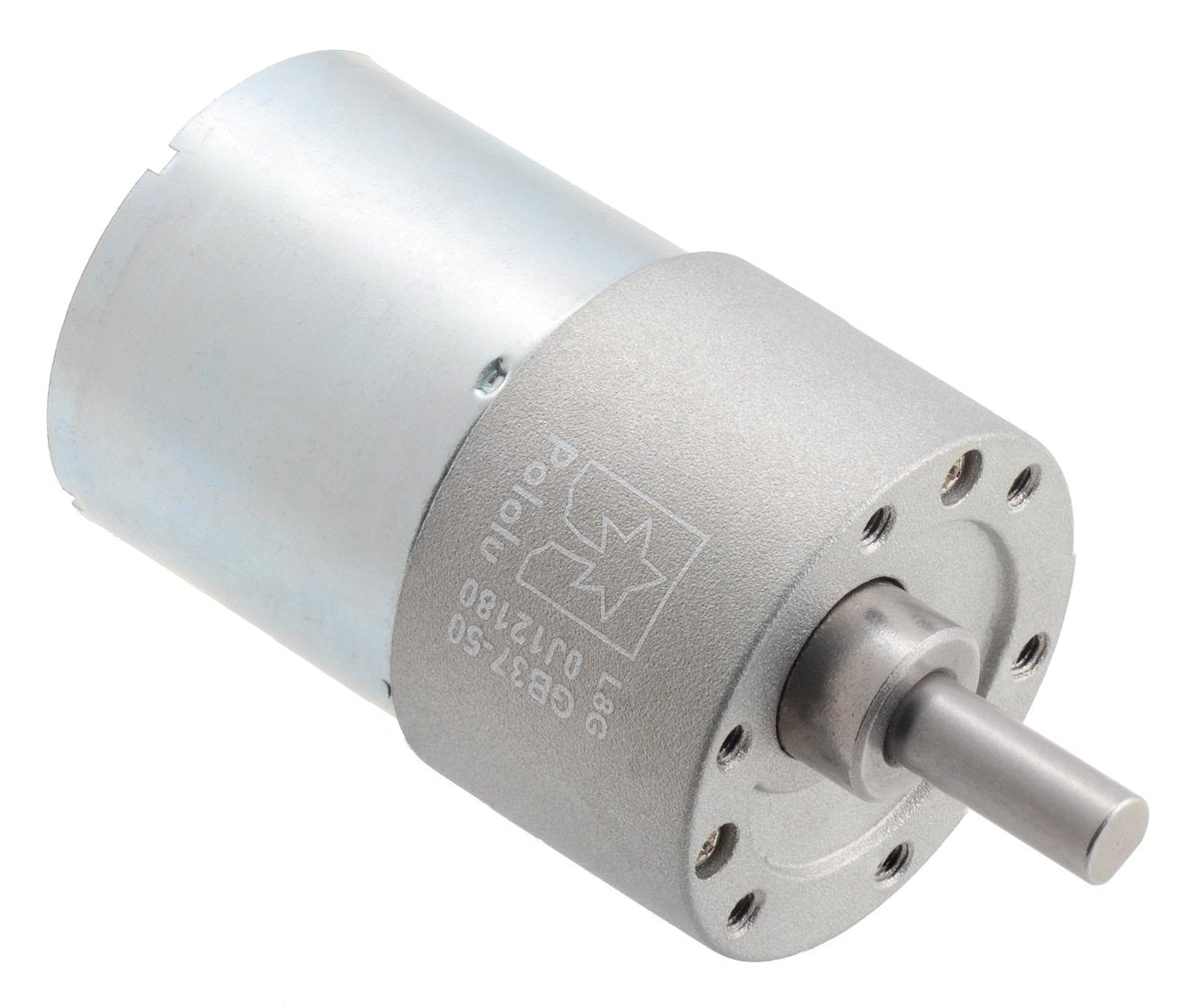

Here in the specialist shop, you can choose from numerous versions of DC motors. For model making and similar applications, we usually recommend simple DC motors or DC gearmotors. Motors with gearboxes increase the torque through the gear ratio, while simple DC motors have no additional gearbox.

If you want to buy a DC motor, you should first determine the specific requirements for load, speed and torque.

The most important criteria for DC motors are:

- Supply voltage in V

- Speed in rpm

- Gear ratio for geared motors

- Dimensions

- Weight

▶︎ You can find all the essential information on the individual product pages.

Perfect control for your DC motor

Our online shop is your one-stop source for all the components you need. You can also purchase the perfect DC motor controller in our DC motor section. We also offer a wide selection of controllers. Pay attention to criteria such as the type and number of interfaces.