How a load cell works

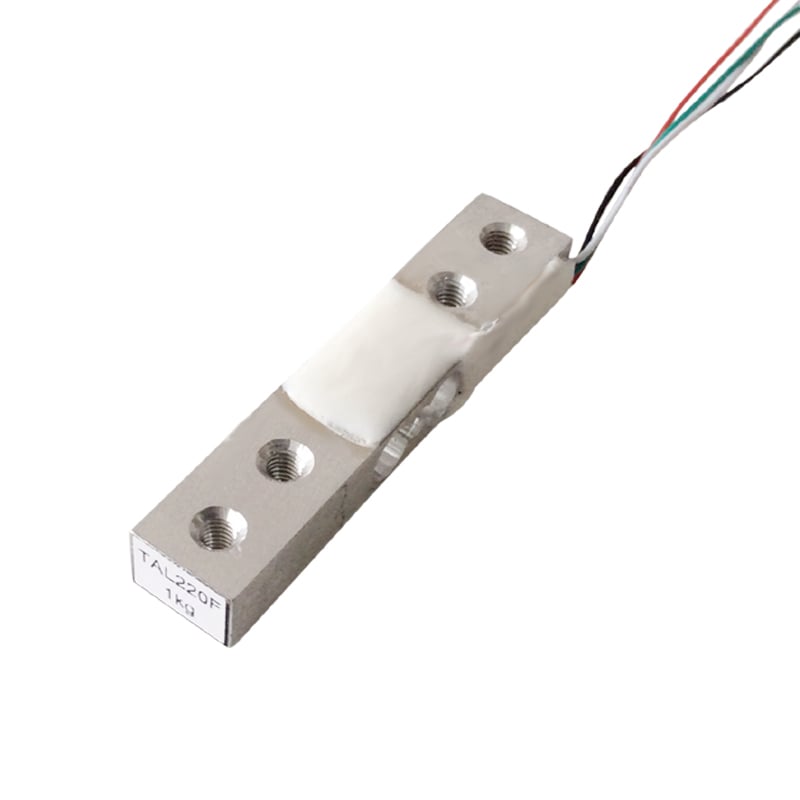

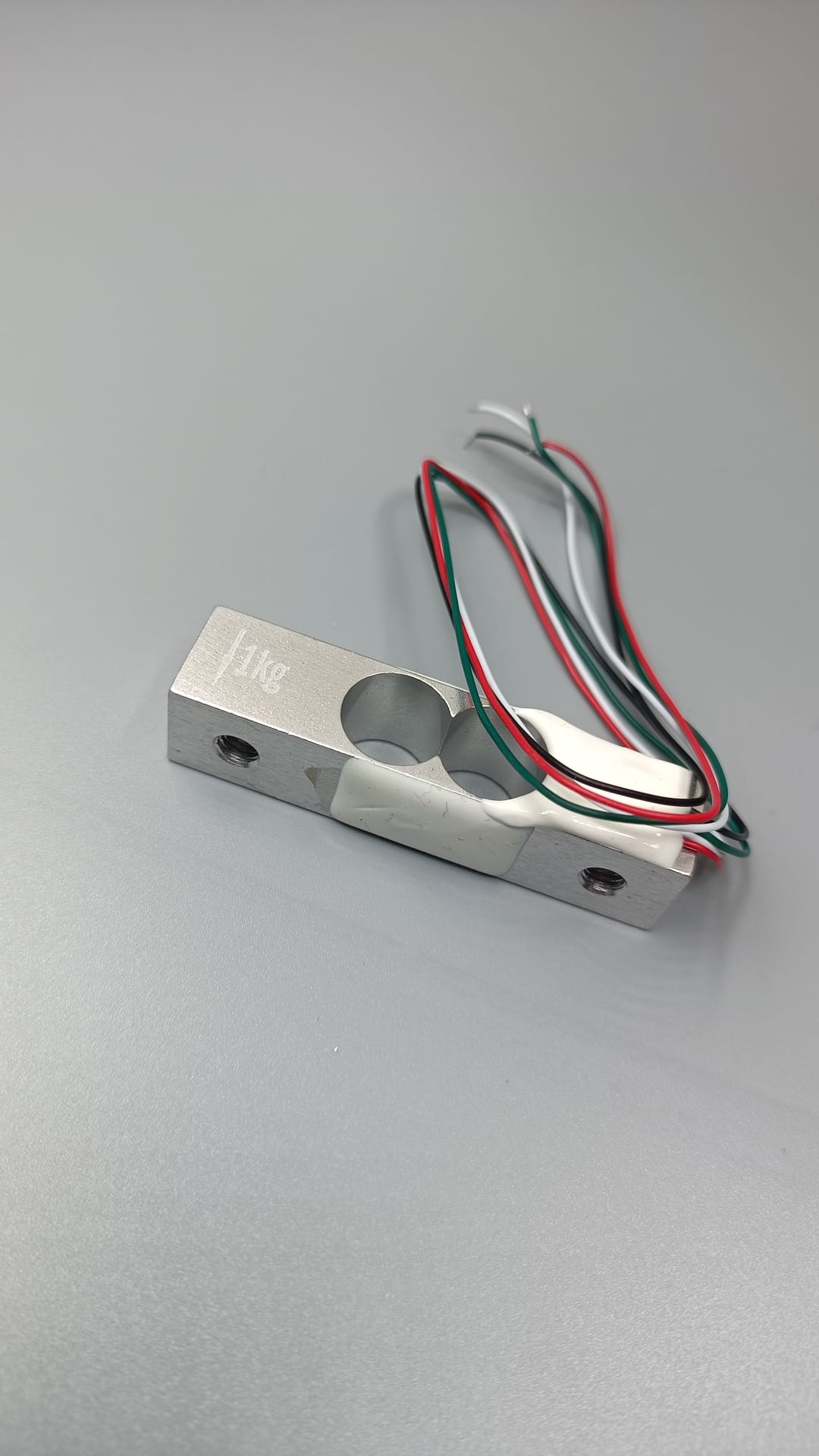

Load cells are a specific type of force sensor used to measure weight. The measurement is performed mechanically and electronically: the load cell converts a mechanically induced change into an electrical signal. These load cells usually consist of the following two components:

- Spring body

- Strain gauge

When users install a load cell, they usually want to measure a weight load from above. A typical example is a load cell in a precision scale, as used in many laboratories. In this case, users place a specific object on the platform of the precision scale, and the weight acts on the spring body. The strain gauge has an electrical resistance – this value reacts immediately to deformations. A downstream electronic circuit evaluates the change in electrical resistance and converts it into a specific weight.

From miniature load cells to load cells for heavy loads

If you want to equip yourself with a load cell, you can choose from a wide range of designs. The intended environment is an important factor here. A load cell can be small or large and is available in rod and round shapes. Frequently used basic types are:

- Platform load cells: weight from above

- Bending beam load cells: several load cells, weight also from above

- Tension load cells: weight from below

For laboratory measuring devices, kitchen scales and similar items, you need miniature load cells. These often contain double bending beams as spring elements for small loads. Large-area and heavy-duty load cells, which are equipped with a shear bar as a spring element, for example, are suitable for other purposes.

The enormous importance of load cells in a wide range of environments

Weighing is indispensable in many places. A glance into private households shows this. Many consumers own kitchen scales, letter scales and bathroom scales, among other things. They also have electrical appliances such as washing machines that contain load cells.

Weighing cells of various designs also perform important functions in industry and logistics. Examples include:

- Filling food

- Packaging various products where weight is important

- Quality control during the manufacturing process

- Measuring the fill level in containers by weight

Medical measuring devices, scales for research laboratories and more: miniature load cells and all other variants can be found in a wide range of areas. Buy reliable components here at EXP Tech – from small load cells in round designs to load cells for heavy loads!

Buy load cells for your project: Tips

When choosing the perfect load cell, the two criteria of nominal load and limit load play a key role. The nominal load refers to the maximum weight up to which the load cells can be calibrated. You can rely on accurate weight measurement up to this value. The limit load, on the other hand, indicates the weight that the load cell can physically withstand. If this value is exceeded, the spring body may become deformed.

The measuring accuracy is also relevant. A load cell for a precision scale has a measurement accuracy of at least 0.1 g. Much more precise load cells are used in research laboratories in particular. In other areas, intervals of 1 g or more are sufficient. In some industrial areas, it is sufficient to measure the mere presence of an object. In these cases, the reading accuracy can be significantly less precise, depending on the weight of the objects in question.

At EXP Tech, you can find the ideal load cells from brand manufacturers such as HT Sensor. Compare the components – you will find all the technical details on the individual product pages!