Description

Note: The QTR-L-1A reflectance sensor requires an analog input to take readings. The similar QTR-L-1RC reflectance sensor is available with a digital I/O-compatible output.

Functional Description:

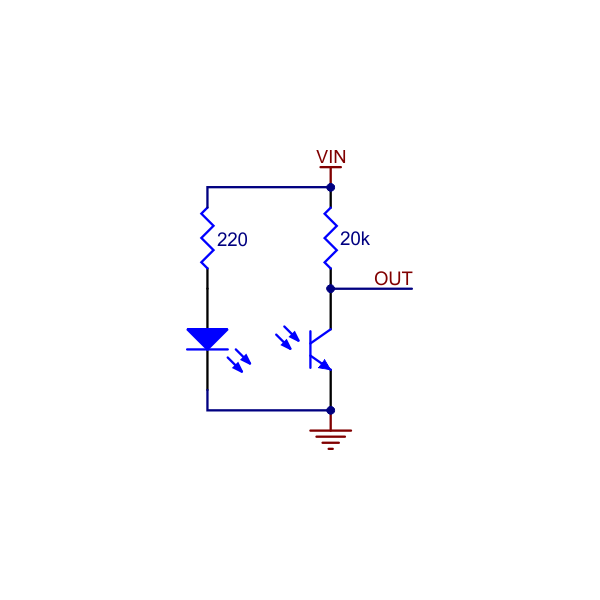

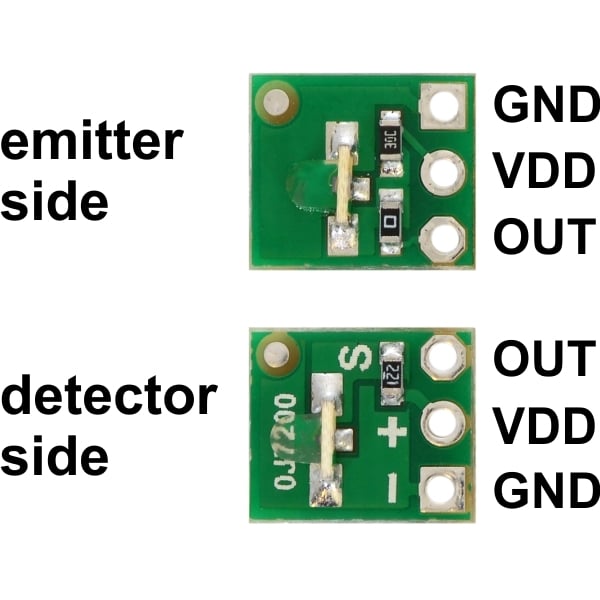

The Pololu QTR-L-1A reflectance sensor carries a right-angle infrared LED and a right-angle phototransistor, both pointing toward the front edge of the board. The phototransistor is connected to a pull-up resistor to form a voltage divider that produces an analog voltage output between 0 V and VIN (which is typically 5 V) as a function of the reflected IR. Lower output voltage is an indication of greater reflection.

The LED current-limiting resistor is set to deliver approximately 17 mA to the LED when VIN is 5 V. The current requirement can be met by some microcontroller I/O lines, allowing the sensor to be powered up and down through an I/O line to conserve power.

This sensor was designed to be used with the board perpendicular to the surface being sensed, and narrow-angle lenses built into the infrared LED and phototransistor packages allow it to be effective to a range of about 1? (25 mm). Because of its small size, multiple units can easily be arranged to fit various applications such as line sensing and proximity/edge detection. The QTR-L-1A is sold in packs of two units.

For a similar sensor that can be used with the board parallel to the surface, but with shorter range, please see the QTR-1A reflectance sensor.

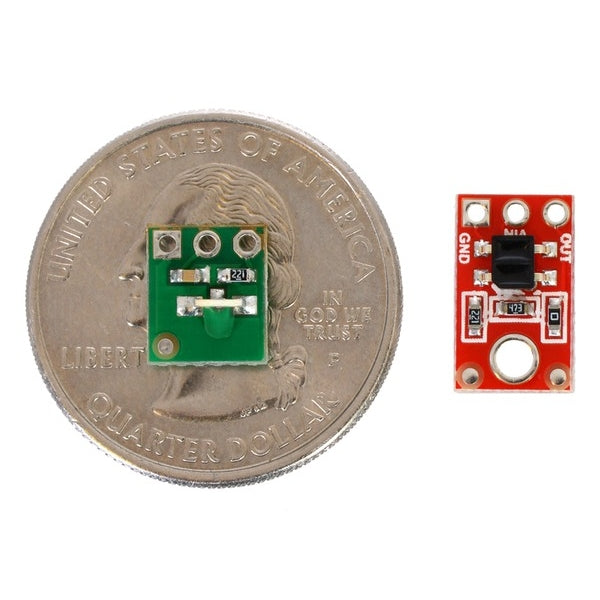

QTR-L-1RC reflectance sensor on a quarter next to a QTR-1A reflectance sensor.

Specifications:

- Dimensions: 0.3? × 0.35? × 0.12? (without optional header pins installed)

- Operating voltage: 5.0 V

- Supply current: 17 mA

- Output format: digital I/O-compatible signal that can be read as a timed high pulse

- Optimal sensing distance: 0.125? to 0.25? (3 mm to 6 mm)

- Maximum recommended sensing distance: 1? (25 mm)

- Weight without header pins: 0.006 oz (0.2 g)

Interfacing with the QTR-L-1A Output

There are several ways you can interface with the QTR-L-1A output:

- Use a microcontroller?s analog-to-digital converter (ADC) to measure the voltage.

- Use a comparator with an adjustable threshold to convert the analog voltage into a digital (i.e. black/white) signal that can be read by the digital input line of a microcontroller.

- Connect the output directly to the digital input line of a microcontroller and rely upon its internal comparator.

This last method will work if you are able to get high reflectance from your white surface (so that there is a large output voltage difference over black and white surfaces), but will probably fail if you have a lower-reflectance signal profile. The following table shows some typical output voltages from the sensor over different surfaces and at different distances:

| White surface | 3/4? black electrical tape | |

|---|---|---|

| 0.25? distance | 0.2V | 3.8V |

| 1? distance | 2.4V | 3.5V |

Ambient light, especially sunlight, can affect the sensor readings significantly. If the output voltage from the QTR-L-1A is consistently low, you might need to add shielding around the sensor or mount it in a different location to reduce interference from outside light sources.

Pololu AVR library provides functions that make it easy to use these sensors with our Orangutan robot controllers; please see the QTR Reflectance Sensors section of Pololu's library command reference for more information. We also have a Arduino library for these sensors.

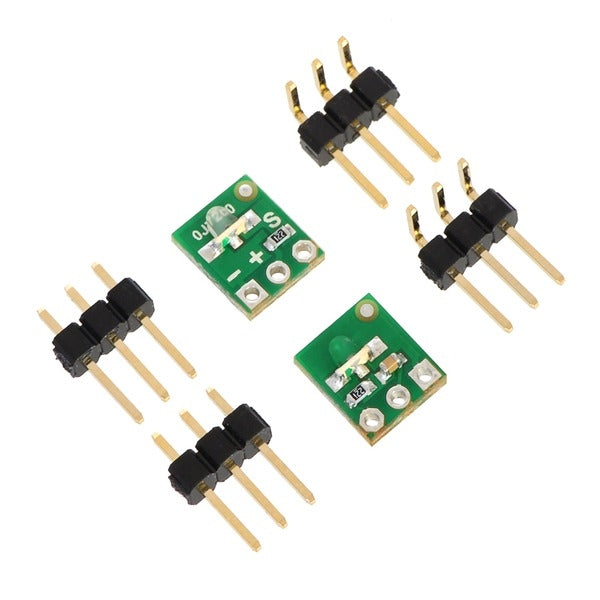

Included Components:

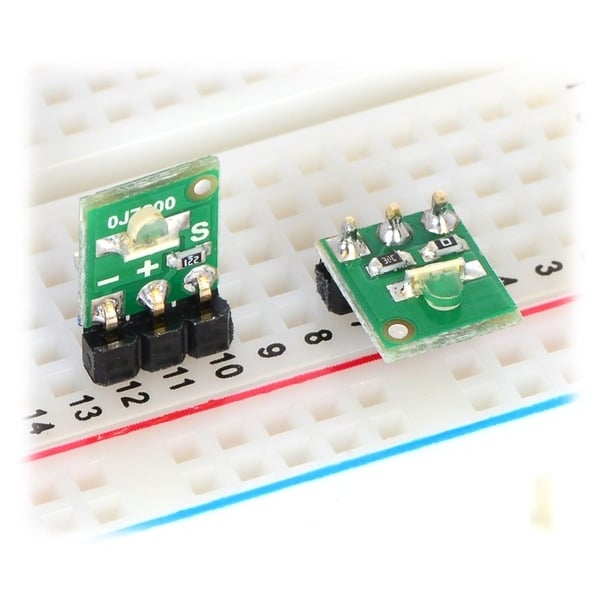

Each pack of two reflectance sensors includes sets of straight male header strips and right-angle male header strips, which allow you to mount them in the orientation of your choice. You can also solder wires, such as ribbon cable, directly to the pads for the most compact installation.

QTR-L-1A or QTR-L-1RC reflectance sensor (2-pack) QTR-L-1A and QTR-L-1RC reflectance sensors mounted

with included header pins. in a breadboard.

Documents:

Encrypted payment

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Additional information

Customs tariff number:

Country of origin:

This depends on where you are located. Once the order has been handed over to UPS, the delivery time in Germany is approx. 2-3 days, within Europe approx. 1 week.

We dispatch our articles with our shipping partner UPS.

If we have not yet answered your question, you can contact us and we will get back to you as soon as possible.

You might also like

Recently viewed