How do servo motors work? Sensor-based control for maximum precision

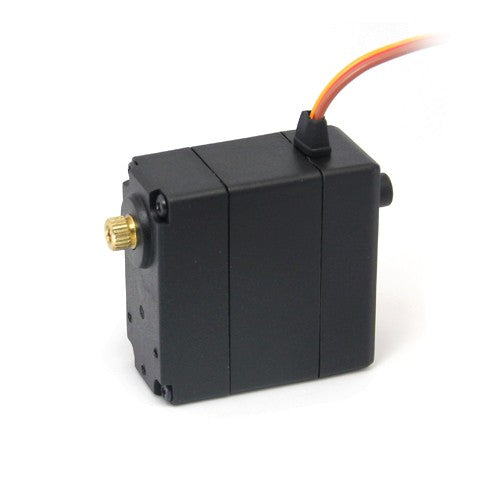

The special feature of servo motors is the precise control of position, torque and speed. This is made possible by the following components:

- Servo motor: Various motor types such as synchronous, asynchronous, DC or AC motors are possible. The decisive difference to other motors is the integrated sensor for determining the position.

- Servo controller: This serves as an interface between the motor and the control system. It converts digital control commands and ensures precise control.

The difference between a stepper motor and a servomotor: precise control vs. repeatable movement

Servo drives enable exact positioning, which is why they are often used in printer rollers or robotic applications.

A stepper motor offers similar functionality, but works without a feedback sensor. While servo motors are particularly suitable for applications requiring the highest precision, stepper motors come into their own in areas where repeatable, step-by-step movement is required, such as 3D printing or CNC technology.

The advantages of servo motors: precise control, low maintenance, long service life

Servo motors offer numerous advantages. They are characterised by their high precision, efficiency and versatility.

- Precise control: Exact control over position, torque and speed.

- Automated control: Use with software solutions such as servo motors with Arduino.

- Cost efficiency: Combination of low acquisition costs, minimal maintenance and a long service life.

Servo motors in industry, robotics and model making – a wide range of applications

Thanks to their precise control and high reliability, servo motors are indispensable components in many technical fields. They enable precise movements in manufacturing and play a central role in robotics and model making.

- Manufacturing technology (e.g. printer rollers)

- Robotics and automation

- Model making (e.g. Tiny Servo Motor)

Servo motors for every need – a wide selection and expert advice

In our shop, you will find a wide range of high-quality servo motors and controllers in a variety of designs. You can find the technical specifications on the respective product pages or get personal advice from our experts.

Frequently asked questions about servo motors

Recently viewed